|

MULTIWIR

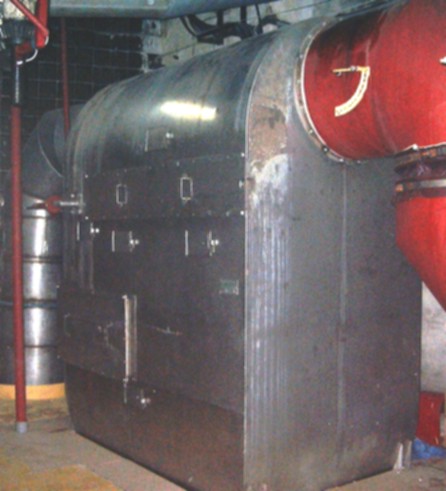

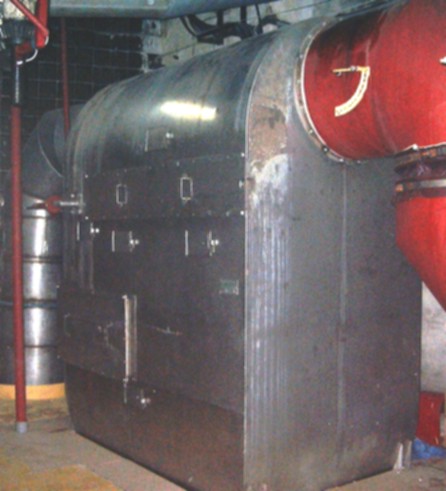

dust separator operates as a wet deduster. The apparatus consists of

two chambers. Both are equipped with Multiwir rectangular packings made

from perforated polypropylene slats. The first chamber, equipped

additionally with spray nozzles, operates as an actual deduster. The second

chamber is assigned for droplet separation.

The gas stream entering the apparatus flows downwards cocurrently with the

liquid through the packing in the first chamber. Dust particles, subjected

to centrifugal force, settle on packing slats and are rinsed by the

liquid. Droplets entrained by the gas stream are stopped in the second

chamber. They settle on the packing surface and drop.

The separation efficiency of the Multiwir sugar-dust separators has been

measured in Sugar Factory “Zbiersk” (Poland) during sugar campaign 2001.

The measurements concerned separation of sugar dust emitted

by a fluid bed dryer of a throughput 400 tons of sugar/24h. The average

amount of sugar separated was about 3 tons/24h. The emission of sugar

dust turned out to be about 3 kg/24h. Hence, the separation efficiency

reached 99,9%, while the pressure-drop in the apparatus was below

700 Pa. |

|